Sprinkler wiring problems are frustrating because they rarely fail in obvious ways. One day a zone works. The next day it doesn’t.

A valve gets replaced. Nothing changes. Then the system works again—for a week.

That’s because many sprinkler system failures aren’t mechanical at all. They’re electrical. And electrical faults underground don’t announce themselves clearly. They mimic bad valves, faulty controllers, or programming issues, which leads to their frequent misdiagnosis.

Sprinkler fault locating isn’t guesswork. It’s a precise diagnostic process that finds underground wiring failures. It does this accurately, efficiently, and without damaging your lawn.

Quick Takeaways

Quick Takeaways

- Most sprinkler failures are caused by hidden wiring faults, not bad valves

- Open circuits, shorts, and common wire breaks are the most common issues

- Fault locating tools allow technicians to find breaks without digging blindly

- Replacing parts without locating the fault usually wastes time and money

What Is Sprinkler Fault Locating?

Sprinkler fault locating is a diagnostic service focused on identifying electrical failures within a sprinkler system’s wiring. Instead of replacing valves, solenoids, or controllers and hoping for the best, fault locating pinpoints where the electrical signal is failing—often underground and out of sight.

The goal isn’t to swap parts. The goal is to find the exact location of the problem so it can be repaired correctly the first time.

Common Sprinkler Wiring Faults That Require Locating

1. Open Circuit Faults

An open circuit means the electrical path is broken. The controller sends power, but it never reaches the valve. When this happens, zones won’t activate at all.

Open circuits usually occur when wires are cut, stretched, or deteriorate underground due to age, soil movement, or past digging. From the surface, everything looks fine. Electrically, the circuit is incomplete.

2. Short Circuit Faults

A short circuit happens when damaged wire insulation allows conductors to touch—either each other or the soil. Shorts can blow controller fuses, trigger error codes, or shut down multiple zones at once.

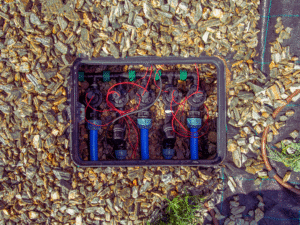

These faults often come from crushed wiring, rodent damage, or water intrusion inside valve boxes.

3. Broken or Failing Common Wire

The common wire is shared by every valve in a sprinkler system. When it fails, multiple zones stop working—or behave erratically.

This is one of the most commonly misdiagnosed issues because it looks like several valves failed at the same time. In reality, the problem is a single broken or corroded common wire somewhere along the run.

4. Intermittent Wiring Faults

Intermittent faults are the hardest to diagnose without proper tools. These occur when wiring is partially damaged, corroded, or affected by moisture.

The system may work at times and fail at others. This can lead homeowners to replace good parts while the real problem stays hidden underground.

Signs You Likely Have a Wiring Fault (Not a Valve Issue)

If you’re seeing one or more of these symptoms, wiring—not valves—is usually the real problem:

If you’re seeing one or more of these symptoms, wiring—not valves—is usually the real problem:

- Zones not responding from the controller

- Controller shows errors or blown fuses

- Multiple zones failing at once

- Valves work manually but not electrically

- Problems return after “repairs”

When fixes don’t stick, that’s a strong indicator the fault was never actually located.

How Sprinkler Fault Locating Actually Works

This is where professional service separates itself from trial-and-error repairs.

Step 1: Controller and Circuit Testing

Technicians begin at the controller, testing voltage output, resistance, and circuit integrity. Each zone is tested to see if the controller sends power correctly. It also checks if the circuit is open, shorted, or overloaded.

Step 2: Solenoid and Field Verification

Before chasing wiring faults, solenoids are tested to confirm they’re functioning properly. This step stops unnecessary wire tracing when the problem is a simple component failure. It also confirms when it is not.

Step 3: Wire Path Analysis

Sprinkler wiring doesn’t always run in straight lines. Fault locating involves identifying how wires are routed through the yard so diagnostics follow the actual path—not assumptions.

Step 4: Electronic Fault Locating Equipment

Using wire tracers and fault locators, technicians send a signal through the sprinkler system wiring. Changes in signal strength indicate where a break, short, or failure exists underground—often within a very small area.

Step 5: Targeted Excavation and Repair

Once the fault is pinpointed, only the affected section is exposed. Repairs are made precisely, minimizing disruption to turf, landscaping, and hardscaping. No blind trenching. No unnecessary digging.

Why DIY Sprinkler Wiring Repairs Usually Fail

DIY troubleshooting often stops at continuity tests. The problem is that continuity alone doesn’t reveal where a fault exists—or whether it’s intermittent.

Homeowners commonly replace valves, solenoids, and even controllers while the wiring fault remains untouched. When problems keep coming back, it usually happens because someone never located the real issue and just worked around it temporarily.

When Fault Locating Is Better Than Rewiring the System

Full rewiring sounds like a clean solution, but it’s rarely necessary. Fault locating allows targeted repairs that cost less, disturb less of your yard, and preserve existing wiring that’s still in good condition.

Rewiring only makes sense when wiring is universally degraded—not when a single fault is causing system-wide issues.

How Long Sprinkler Fault Locating Takes

Most sprinkler fault locating jobs take one to three hours, depending on several factors:

- Number of zones

- Depth and routing of wiring

- Type of fault being located

Accurate diagnostics upfront save far more time than repeated repairs spread over weeks or months.

FAQ: Sprinkler Fault Locating Questions Homeowners Ask

What causes sprinkler wires to fail underground?

Common causes include rodent damage, corrosion, poor installation practices, soil movement, moisture intrusion, and damage from landscaping or construction work.

Can a sprinkler wiring fault damage the controller?

Yes. Short circuits and overloaded wiring can damage transformers, blow fuses, or harm internal controller components if left unresolved.

Is fault locating possible without digging up the whole yard?

Yes. Modern fault locating tools allow technicians to pinpoint wiring failures accurately, so only a small, targeted area needs to be exposed.

How much does sprinkler fault locating usually cost?

Costs depend on system size, fault complexity, and access conditions. However, fault locating is typically far less expensive than repeated part replacements or full rewiring.

Should I replace valves before locating wiring faults?

No. Replacing valves before locating wiring faults is backwards and often leads to unnecessary expenses without solving the underlying problem.

Why Professional Fault Locating Saves Money Long-Term

Accurate fault locating prevents repeat service calls, unnecessary part replacements, and escalating damage to controllers or wiring. Fixing the right problem once is always cheaper than fixing the wrong problem repeatedly.

Schedule Professional Sprinkler Fault Locating in Dallas, TX

If your sprinkler system keeps failing or acting strangely, it’s time for a clear diagnosis. You need more than guesswork.

If your sprinkler system keeps failing or acting strangely, it’s time for a clear diagnosis. You need more than guesswork.

Lawn Sense offers expert sprinkler fault locating in Dallas, TX, and nearby areas. We use special tools to find wiring problems quickly and accurately. We protect your lawn, your landscaping, and your budget—because Lawn Sense means no nonsense.

Schedule your sprinkler fault locating service today and get the problem fixed right the first time.